Heat, Hurricane, and Fire Season

It has been a busy year for emergency managers. Record-breaking heat waves and air quality impacts from widespread wildfires affected much of the country in June, the Atlantic hurricane season is off to a fast start, and the summer has just begun. We’ve collected a list of agency websites that offer predictive models and resources to help you update your preventative measures and emergency response plans for your business and your home in this season of environmental risks.

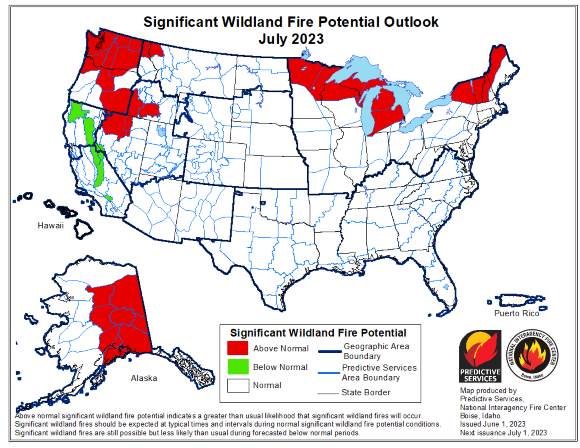

WILDFIRES: The National Interagency Coordination Center (NICC) publishes a

National Significant Wildland Fire Potential Outlook on the first of each month that provides general reports and maps on fire potential, giving risk managers and community members an outlook for the following month and a trend forecast for the next three months. They also provide information, news, and statistics on

current incidents and risks.

HURRICANES:

GULF COAST:

-

The Gulf Intracoastal Canal Association (GICA) leads the Gulf Coast Inland Waterways Joint Hurricane Team (JHT), which reviews and updates the Gulf Coast Inland Waterways Joint Hurricane Response Protocol each year. This year’s JHT meeting was held on May 25. The updated Protocol and presentations from attending agencies including the U.S. Coast Guard, U.S. Army Corps of Engineers, National Oceanic and Atmospheric Administration, and National Weather Service can be accessed on GICA’s website.

ATLANTIC COAST:

-

The USCG Fifth District has an updated list of resources available on its Homeport site.

-

The USCG Seventh District issued a press release that lists preparedness tips and links resources for the Southern Atlantic Coast and Caribbean.

-

Through the Coast Guard-AWO Safety Partnership’s Atlantic Regional Quality Steering Committee, AWO works with members and the USCG to send out an updated list of key contacts for every Sector and MSU for stakeholders to use in the event of an emergency. AWO’s Vice President – Atlantic Region Brian Vahey is updating the list for 2023 and will be posting it on the AWO website soon. For more information, contact bvahey@americanwaterways.com.

NATIONAL:

-

The National Hurricane Center (NHC) maintains a resources page that provides educational materials and resources to prepare for hazardous tropical weather.

-

The National Weather Service offers a webpage of Hurricane Safety Tips and Resources.

HEAT: According to the National Weather Service,

extreme heat has been the number one weather-related cause of death in the U.S. for the last three decades. Heat injuries are preventable. Providing up-to-date heat index information to captains and managers, establishing training programs to educate employees about the dangers of heat injuries and how to take preventative measures, and establishing work/rest protocols for crews is essential to protecting our mariners on deck. Resources for establishing or updating your program are listed below:

Safety Professionals’ Corner

|

Jim Peschel started his maritime career with the U.S. Coast Guard. During his 11 years of service, he participated in pollution response, Port State Control vessel boardings, search and rescue operations, and waterways management. In 2000, Jim joined the private sector, working with the National Response Corporation as Manager of Marine Operations; with Foss Maritime Company as Quality Assurance Manager; and with Holland America Line as Senior Director of Environmental Operations. In 2018, Jim joined The Vane Brothers Company, where he now works as Health, Safety and Environmental Manager for Vane’s West Coast Operations. Jim serves on AWO’s Safety Leadership Advisory Panel as Coastal Safety Committee Chair. |

What are your safety program priorities for 2023?

Fall overboard prevention is a crucial focus area. Personally, I am looking into the feasibility of using inflatable PFDs in different applications. Our vessels carry Type I lifejackets to meet regulatory needs, but finding a comfortable PFD the mariners will actually wear on deck is my focus. Inflatable Type V work vests are designed to turn a person face up and keep their head above water, and they often offer more buoyancy when compared to work vests that use inherently buoyant material, like a vinyl dipped foam work vest. It is not just about comparing the specifications though. There must be testing, inspections and training programs for equipment to ensure it is utilized as designed.

Another fall-overboard-related safety initiative I am working on is ladder and gangway safety. I want to be sure our crews have access to and are using the right equipment for the job, and that the equipment is used according to Vane Brothers’ policy and the manufacturer’s instructions. This is an ongoing project. For portable ladders, it is about making sure they are adequately rated, in good working order, properly staged with secure footing and tied off correctly so they remain effective during changes in draft. For gangways, the landing area and tie-off is crucial, especially with large tidal variation, as is the use of handrails, and inspections are important to be sure they are free of damage. For pigeonhole ladders, I want the crews to remain vigilant when using them. You must be intentional about your first step on and last step off. To address this, we encourage marking the first step from above so you know where to anticipate secure footing. We have also added handholds at the top of some pigeonhole ladders to help users step off safely with a secure point of contact to grab onto.

One other thing I am working on to prevent falls is education about crossing the gap between vessels and/or shore. The gap can be large, the step down further, or there could be shifting between the two pieces of equipment. I stress the importance of being intentional when you step across a gap or off a ladder or gangway. Hesitation, inattention, carrying a load or other extenuating circumstances can change a small step into a big problem.

Can you talk about Vane Brothers’ safety culture and an example of how you promote culture across the organization?

Vane Brothers is a family company with three generations currently actively involved in the operations. The owner’s sons are maritime academy graduates and serve as vessel managers in a regional office. They have daily interaction with the mariners so the importance of ensuring safety is not just an idea, it is firmly rooted in a family culture. We are committed to the highest standards of quality and safety in the maritime industry and we work hard to promote the protection of our workforce and the environment at all times.

All of this is part of my message to each mariner about the importance of taking personal responsibility for their own and their shipmates’ safety. I want them to understand their role in the safety chain. The company policies are one layer of protection, physical barriers are another, and choosing the right personal protective equipment is a third layer of protection. It ultimately comes down to the individual having the skills and knowledge not to put themselves in harm’s way. I want them to have the confidence to speak up when they do not understand a task or when it is not going as planned. I do that by supporting them, letting them know that the company will always back them when they stop an activity to reassess the risk if things are not going as discussed in their pre-task briefing.

We had a motto at one of my Coast Guard duty stations. Our mission was to protect the man from the sea and the sea from man. I see this as the basis for my current HSE role years later. Protecting man from the sea is my safety mission at Vane where I look to identify risk and then find ways to minimize or mitigate it to make the task safer and incident-free. The part about protecting the sea from man encompasses my environmental stewardship role – striving to keep spills from happening and looking for other ways to minimize our operational footprint to be a more sustainable industry.

I believe that it is my charge to be available to our crews and I make visits a priority. I am shoreside, but I don’t want that to be a barrier to communication between crews and myself – so I make it a priority to be present often on the boats, and I always endeavor to lead by example.

We strive to deliver a consistent message about our safety priorities and culture. When I and the other shoreside managers go to the boats, we utilize vessel visit checklists tailored to the job of the vessel, the crew we are talking to, and the position in the company of the visiting manager. The visits I make are not just designed to promote our safety culture priorities, but also to learn what we can do better. The cornerstone of our safety management system is the use of the corrective action process. This process requires the participation of everyone in the organization. When I visit, I want to discuss past mistakes and begin or continue a corrective action process to prevent those mistakes from happening again in the future.

Additionally, and maybe most importantly, I use my visits to talk up the good things our crews are doing. I make it a point to make positive comments as well as suggestions for improvement. I want to build up crew morale by pointing out the professional and extraordinary things that our mariners are doing each day on our vessels. It is my strong belief that if you are going to the vessel to look for something wrong you have set yourself up to miss out on dialogue about opportunities for improvement.

My visits need to be valuable to the crew. I am looking for champions and I want to recognize them in front of their peers. I am asking our crews to follow our policies and procedures and also asking them to be the leaders of our company’s safety and environmental programs. I am asking them to educate new crew members, vendors, customers, and the community about Vane Brothers’ safety culture. I am asking a lot, and the least that I can do is thank our crews at every opportunity during a visit. If there is something wrong, we need to look at our management system – not just the individual. If there is something right and we promote it, it builds a sense of ownership for those safety advocates, the men and women that are working hard on our vessels each day.

You have been highly successful in your maritime career! Can you share what you like about our industry and advice for someone who is considering maritime transportation as a career?

I started my maritime career in high school working on an oyster boat in Cape Cod. I then went to the USCG for 11 years, and I believe that military service is important and would encourage young people to consider it. The Coast Guard gave me an education, taught me personal responsibility, and prepared me for a career in the private sector. The skills I learned in the service translated especially well to the maritime industry.

My career with the Coast Guard was not the end of my response to emergencies. After leaving active duty I moved over to the National Response Corporation, better known as NRC. That role gave me the opportunity to help people in emergency situations and to mitigate the damage following an incident. This early career path gave me a great perspective on how to work safely and efficiently, how to plan for emergencies and what to do when they happen.

Outside of work, I have had the opportunity to share my expertise speaking with students at the University of Washington’s Graduate School of Marine and Environmental Affairs. I speak to graduating students about how to promote safety for employees and how to protect the environment. My advice for them is instead of working for a non-profit or governmental agency, go to work for a large energy company. Work to change policy from within. Work to find energy solutions within the organizations that will shape the way we power our lives in the future. Promoting good policy and values within the multi-national organizations that control a great percentage of our global resources is the most direct way to make an impact and to shape the future of your family and the environment.

A Recipe for a Healthier You

Grilled Chili Steak & Peppers

The 4th of July is a great time for a BBQ! This recipe can be done in the oven for those of you on a vessel that cannot use an open-flame grill. This recipe was adapted from

Taste of Home.

|

PREP TIME

|

TOTAL TIME

|

SERVINGS

|

|

5 min

|

35 min

|

4

|

Ingredients

|

2 tablespoons chili sauce

|

1 medium green pepper, cut into strips

|

|

1 tablespoon lime juice

|

1 medium sweet yellow pepper, cut into strips

|

|

1 teaspoon brown sugar

|

2 teaspoons olive oil

|

|

1/2 teaspoon crushed red pepper flakes

|

1 small garlic clove, minced

|

|

1/2 teaspoon salt, divided

|

1/8 teaspoon pepper

|

|

1 beef top sirloin steak (1-1/4 pounds)

|

1/4 cup reduced-fat sour cream

|

|

1 medium onion, halved and sliced

|

1 teaspoon prepared horseradish

|

Directions

-

Combine the chili sauce, lime juice, brown sugar, pepper flakes and 1/4 teaspoon salt; brush over steak. Broil steak 4-6 inches from the heat for 5-7 minutes on each side or until meat reaches desired doneness (for medium-rare, a thermometer should read 135°; medium, 140°; medium-well, 145°).

-

Meanwhile, in a large skillet, sauté onion and green and yellow peppers in oil until tender. Add the garlic, pepper and remaining salt; cook 1 minute longer. In a small bowl, combine sour cream and horseradish. Slice steak and serve with pepper mixture and sauce.

Nutrition

|

Calories: 265kcal

|

Fat: 9g

|

Sodium: 491mg

|

Cholesterol: 62mg

|

|

Carbohydrates: 12g

|

Saturated Fat: 3g

|

Sugar: 8g

|

Protein: 32g

|

AWO is invested in the wellness of our maritime family. Caitlin Kidd, AWO’s Manager - Membership & Digital Operations, is also a nutrition expert. She holds a Bachelor of Science degree in dietetics from the University of Northern Colorado and is passionate about helping others develop healthy habits through sharing the positive impact of good nutrition and making quality dietary choices. Do you have a recipe or an idea for a healthy meal? Share it with Caitlin by sending it to

safety@americanwaterways.com – you could be included in a future newsletter!

Quick Safety Tip:

Clean your hardhats to avoid skin infections like cellulitis, acne, abscesses, or MRSA. That pad or strap that supports the hard hat suspension system is a perfect medium for bacteria. Wipe with a soft cloth and a small amount of soap and warm water at least once a week to prevent irritation and infection.

|

What is a High Potential Learning Value Near Miss?

A High Value Near Miss or Stop Work event is one that potentially prevents an injury or incident by:

-

Identifying a hazard in the workplace that could result in injury or incident; and

-

Providing an opportunity for reflective learning that has broad application to other mariners or operations.

-

If the hazard is left uncontrolled, it has a medium to high probability of occurring.

|

AWO High Potential Learning Value Near Miss

Near Miss and Stop Work events are leading indicators that provide operators with an opportunity to identify and address weaknesses in a safety management system before a hazardous condition or lack of procedure contributes to an injury or incident.

We are highlighting recent High Potential Learning Value Near Misses submitted voluntarily by AWO members. To submit your own Near Miss or Stop Work event,

please use this form.

Using a Bit as a Step

MEMBER-SUBMITTED NEAR MISS 23-03

A tug and barge unit was docking alongside a ship to conduct a bunker transfer. As the tug and barge unit began mooring operations, a tug deckhand trainee stepped on top of a double mooring bit to reach a mooring fixture on the ship. The experienced tank barge PIC immediately requested the deckhand trainee to step down onto the deck and utilize a pole to deploy the mooring line as standing atop was unsafe and a fall overboard risk.

|

POSSIBLE IMPACTS OF THIS EVENT COULD HAVE INCLUDED:

|

|

1. Fall overboard/drowning.

2. Trapped in between/crush injury or fatality.

|

|

LESSONS LEARNED & FUTURE RISK MITIGATION:

|

|

1. Having an experienced crew member on deck is always a best practice, especially when working with inexperienced crews.

2. Use pre-task meetings to discuss proper mooring techniques and tools.

3. Use this near miss as a safety meeting topic to discuss dangers of standing on fittings/bits, proper mooring procedures, risks of working near the edge of a barge, and the importance of stop work obligation to mitigate risks and prevent incidents.

|

NTSB Highlights the Fire Hazards of Oily Rags on Vessels

The NTSB determined that the probable cause of the fire aboard the Pegasus was spontaneous combustion due to the self-heating of used oil-soaked rags that had been improperly disposed of on the aft deck of the vessel. The day before the fire, the Pegasus owner’s employee had placed a bag with rags soaked with a raw-linseed-oil product under the table on the aft deck. There was no electrical or other heat source noted near where the fire started, and the linseed-oil product container included a warning of this hazard. These facts led to an agreement by all investigators that spontaneous combustion was the likely cause of the fire.

Lessons Learned:

-

Dispose of oily rags properly and according to manufacturer’s instructions. Improperly stored or discarded rags can spontaneously combust as the rags generate heat as they dry.

-

Consider the mooring of vessels that are not crewed and use a fire watch on any vessel that has a risk of fire due to maintenance activities, including surface preparation, painting, or cleaning work that uses chemicals.

-

Do not store combustibles near flammables.

Green Marine Holds GreenTech Conference and Publishes 2022 Performance Report

Green Marine is a leading environmental certification program for North America’s maritime industry.

In early June, Green Marine held its 2023 GreenTech Conference, providing a forum to discuss and learn about the issues prioritized by the program’s environmental performance indicators. AWO’s Director of Safety and Sustainability Mike Breslin moderated the Harbor Craft Decarbonization panel, which featured presentations from Crowley, BC Ferries, Seaspan Ferries, and BC Hydro. The panelists had a robust conversation about industry needs and forecasts for the near- and medium-term development of alternative fuel and electric power propulsion systems, including supply chain issues, infrastructure hardening and upgrades, and the need for broad availability of alternative fuels to support the transition to more sustainable means of powering vessels. A full program can be found on the GreenTech 2023 webpage.

Green Marine released its 2022 Performance Report during the conference, which summarizes the progress of the program’s participants and highlights its plans to update performance indicators for the coming year. To learn more or to join Green Marine, visit its website.

We Can Be HEROes

The

American Waterways Honor & Excellence in Rescue Operations (HERO) Award recognizes rescues undertaken by AWO member company employees that demonstrate selflessness, skill, and bravery. AWO launched the program on March 1, recognizing our first awardees during the Safety Committees’ Winter Meeting. Since then, we have received several additional submissions, demonstrating the great things our mariners are doing every day to protect themselves, their crews, the environment, and the communities in which they operate.

AWO will be making updates to the HERO Award program in the coming weeks, including awarding challenge coins to recognized crews and announcing an exciting program sponsor. Details about how to submit a nomination for the HERO Award and

the submission form can be found on

the AWO website. Please help us thank and shine a spotlight on our industry’s heroic mariners by sending in a nomination.

Subcommittee News

Tankering and Barge Operations Subcommittee

The Tankering and Barge Operations Subcommittee presented on May 22 at the International Liquid Terminals Association (ILTA) International Operating Conference in Houston. Chair Josh Dixon of PSC Group and James Loughlin of Midwest Tankermen presented

Gangway! Insightful Approaches to Marine and Dock Safety.

The next meeting of the group will be held in person at the Coastal and Interregion Safety Committees’ Summer Safety Meeting in St. Louis.

Sign up for the safety meeting on your member dashboard.

Falls Overboard Subcommittee

AWO’s Falls Overboard Subcommittee is made up of carrier and affiliate members with an interest in developing real-world solutions to address falls overboard, the leading cause of fatalities in the barge and towing industry.

The Subcommittee met virtually on April 24 to review its draft report on the prevention of falls overboard and discuss standards, policies, tools, and equipment that may be used to mitigate the risk of falls from an unguarded edge of a barge. Plans are in place to hold virtual meetings in July to continue the review process in anticipation of the report’s presentation at the Safety Committees’ Summer Meeting in St. Louis. If you would like to participate in this subcommittee, please email

safety@americanwaterways.com.

Distracted Operations Subcommittee

The Distracted Operations Subcommittee is working to identify sources of distraction and develop tools to mitigate the risk of distractions as a contributing factor in marine casualties. Through the subcommittee’s work, AWO has published a

Sterile Wheelhouse Guide and a

Deckhand Distracted Operations Guide. The Distracted Operations Subcommittee will meet in July to discuss the draft Guide to Mitigating Distracted Operations. If you would like to participate in this subcommittee, please email

safety@americanwaterways.com.

Environmental Stewardship Working Group

The diverse operational profiles of AWO’s members mean that there is no one-size-fits-all solution for companies looking to reduce their impact on the environment. The Voluntary Environmental Stewardship Best Practices do not create rigid rules; rather, they detail potential practices in a catalog that can serve as a resource for members seeking to take the next steps on their sustainability journey.

If you would like to be a part of the working group, please contact

Leah Harnish.

SSRP – We Need Your Input!

The value of AWO’s Safety Statistics Reporting Program depends on the full participation of all eligible members. This includes carrier members who employ or are responsible for vessel crews in their operations. Please visit the

Safety Statistics Reporting Program website and enter your data for the second quarter of 2023, as well as any historical data that may be missing. Your submission is confidential and crucial to our industry’s benchmarking, advocacy, and safety and sustainability initiatives. If you have any questions, please feel free to contact

mbreslin@americanwaterways.com.

Interregion and Coastal Safety Committees’ Summer Meeting in St. Louis August 16-17

-

AWO’s Safety Subcommittees;

-

The Maritime Administration and the Bureau of Labor Statistics, discussing SafeMTS, a confidential near miss reporting tool for the maritime industry;

-

Researchers funded by the National Oceanic and Atmospheric Administration, presenting and requesting feedback on NOAA noise mitigation programs and vessel design best practices;

-

The Centers for Disease Control and Prevention and the National Institute for Occupational Safety and Health, discussing the human element;

-

Caterpillar®, presenting on sustainable marine engine technology;

-

and more!